10 Best Solder Seal Wire Connectors 2026 in the United States

Winner

Kuject Heat Shrink Solder Seal Wire Connectors Kit 1200PCS, Waterproof Butt Connector Heat Shrink Electrical Terminals, Insulated Solderless Wiring Splice Connectors for Marine Automotive Boat Truck

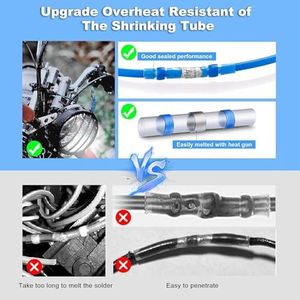

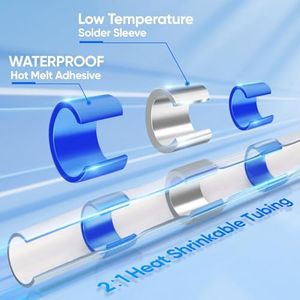

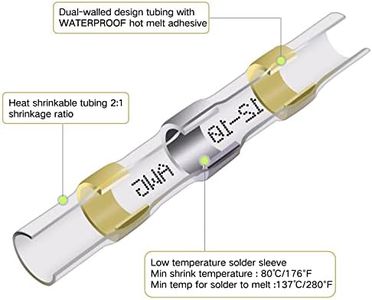

The Kuject Heat Shrink Solder Seal Wire Connectors kit offers a convenient and efficient solution for joining wires, especially in automotive, marine, and truck applications. Its main strength lies in its solderless and crimpless design, which lets you create secure connections using only a heat gun. This makes the process faster and easier compared to traditional soldering or crimping, particularly useful in tight or confined spaces where maneuvering tools can be difficult.

Most important from

43917 reviews

Kuject 600PCS Solder Seal Wire Connector Kit, Solder Seal Butt Terminal Waterproof Insulated Electrical Wire Splice for Automotive Marine Boat

The Kuject 600PCS Solder Seal Wire Connector Kit is designed to simplify the process of connecting wires, particularly in automotive, marine, and boat applications. One of its biggest strengths is the time-saving design; you only need a heat gun to complete the connection, eliminating the need for traditional soldering or crimping. This can be particularly useful for users working in confined spaces where traditional methods can be cumbersome.

Most important from

43917 reviews

Ultimate All-in-ONE Heat Shrink Solder Seal Wire Connectors Kit – Wire Striper, Heat Gun, Kuject 2000PCS Waterproof Solder Stick Butt Connectors, Electrical Wiring Connector Kit for Marine Automotive

The Kuject Ultimate All-in-ONE Heat Shrink Solder Seal Wire Connectors Kit is a comprehensive solution for anyone needing reliable wire connections, especially in automotive or marine environments. It supports a broad range of wire gauges (from 26 to 8 AWG), which means it can handle most common wiring tasks. The kit includes two heat shrink ratios (2:1 and 3:1), giving flexibility to fit different wire thicknesses securely. The solder melting temperature is well-managed by the included 350W heat gun, which reaches up to 752°F (400°C), allowing for fast and clean soldering without the mess and risks of using a lighter or standalone soldering iron. This makes wire sealing easier and safer.

Most important from

115 reviews

Top 10 Best Solder Seal Wire Connectors 2026 in the United States

Winner

Kuject Heat Shrink Solder Seal Wire Connectors Kit 1200PCS, Waterproof Butt Connector Heat Shrink Electrical Terminals, Insulated Solderless Wiring Splice Connectors for Marine Automotive Boat Truck

Kuject Heat Shrink Solder Seal Wire Connectors Kit 1200PCS, Waterproof Butt Connector Heat Shrink Electrical Terminals, Insulated Solderless Wiring Splice Connectors for Marine Automotive Boat Truck

Chosen by 1399 this week

Kuject 600PCS Solder Seal Wire Connector Kit, Solder Seal Butt Terminal Waterproof Insulated Electrical Wire Splice for Automotive Marine Boat

Kuject 600PCS Solder Seal Wire Connector Kit, Solder Seal Butt Terminal Waterproof Insulated Electrical Wire Splice for Automotive Marine Boat

Ultimate All-in-ONE Heat Shrink Solder Seal Wire Connectors Kit – Wire Striper, Heat Gun, Kuject 2000PCS Waterproof Solder Stick Butt Connectors, Electrical Wiring Connector Kit for Marine Automotive

Ultimate All-in-ONE Heat Shrink Solder Seal Wire Connectors Kit – Wire Striper, Heat Gun, Kuject 2000PCS Waterproof Solder Stick Butt Connectors, Electrical Wiring Connector Kit for Marine Automotive

Solderstick Waterproof Solder Seal Wire Connectors Kit, Electrical Insulated Wire Splice Heat Shrink Wire Connectors with 4 Gauges - 12-10, 16-14, 22-18, 26-24 AWG (100)

Solderstick Waterproof Solder Seal Wire Connectors Kit, Electrical Insulated Wire Splice Heat Shrink Wire Connectors with 4 Gauges - 12-10, 16-14, 22-18, 26-24 AWG (100)

340PCS Solder Seal Wire Connectors-haisstronica Marine Grade Heat Shrink Wire Connectors-Butt Splice Wire Terminals for Marine,Electrical with Corrosion and Weatherproof(5Colors/5Sizes)

340PCS Solder Seal Wire Connectors-haisstronica Marine Grade Heat Shrink Wire Connectors-Butt Splice Wire Terminals for Marine,Electrical with Corrosion and Weatherproof(5Colors/5Sizes)

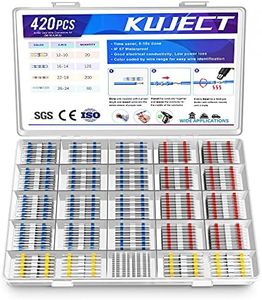

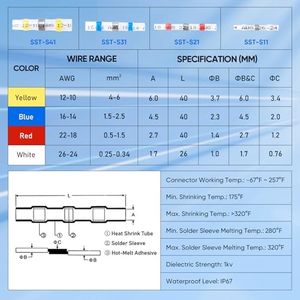

Kuject 420PCS Solder Seal Wire Connectors, Self-Solder Heat Shrink Butt Connector Solder Sleeve Waterproof Insulated Electrical Butt Splice Wire Terminals for Marine Automotive Boat Truck Wire Joint

Kuject 420PCS Solder Seal Wire Connectors, Self-Solder Heat Shrink Butt Connector Solder Sleeve Waterproof Insulated Electrical Butt Splice Wire Terminals for Marine Automotive Boat Truck Wire Joint

TICONN 600 Pcs Solder Seal Wire Connectors, Heat Shrink Butt Connectors, Waterproof and Insulated Electrical Wire Terminals, Butt Splice (600PCS)

TICONN 600 Pcs Solder Seal Wire Connectors, Heat Shrink Butt Connectors, Waterproof and Insulated Electrical Wire Terminals, Butt Splice (600PCS)

350 Pcs Solder Seal Wire Connectors Heat Shrink Butt Connectors Kit Marine Waterproof Wiring Electrical Cable Splice Terminals for Boat Automotive RV Trailer

350 Pcs Solder Seal Wire Connectors Heat Shrink Butt Connectors Kit Marine Waterproof Wiring Electrical Cable Splice Terminals for Boat Automotive RV Trailer

400PCS Solder Seal Wire Connectors-haisstronica Waterproof Heat Shrink Butt Connectors-Self Solder for Marine,Aircraft,Boat,Truck,Stereo,Joint

400PCS Solder Seal Wire Connectors-haisstronica Waterproof Heat Shrink Butt Connectors-Self Solder for Marine,Aircraft,Boat,Truck,Stereo,Joint

haisstronica 400PCS Solder Seal Wire Connectors Kit,26-10 Gauge Marine Grade Heat Shrink Wire Connectors,Waterproof Butt Connectors,Butt Splice Eletrical Wire Connectors Kit(5Colors/5Sizes)

haisstronica 400PCS Solder Seal Wire Connectors Kit,26-10 Gauge Marine Grade Heat Shrink Wire Connectors,Waterproof Butt Connectors,Butt Splice Eletrical Wire Connectors Kit(5Colors/5Sizes)

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.