10 Best Plastic Welders 2026 in the United States

Winner

WELDY 3400W Handheld Plastic Extrusion Welding Machine kit Hot Air Plastic Welder Gun Vinyl Weld Extruder Welder Machine (EX2)

The WELDY 3400W Handheld Plastic Extrusion Welding Machine is a powerful tool designed for professional use in plastic fabrication and civil engineering. With a maximum output of 2.2 kg/h, it is capable of handling extensive welding tasks efficiently. The machine's compact and lightweight design, along with an easy-to-handle structure, makes it ideal for prolonged use without causing fatigue. The dual-sided insertion for welding rods allows for flexibility in welding positions, which can be particularly useful in complex projects.

SWIGRANCE Hot Air Plastic Welder 1600W, Complete Accessories & Nozzles for Plastic Welding Roofing Kit 110V, Vinyl PVC TPO Roof Handheld Hot Air Heat Gun Plastic Welding Torch

The SWIGRANCE Hot Air Plastic Welder is a strong choice for anyone needing to weld or repair thermoplastic materials like roofing membranes, vinyl floors, or car bumpers. Its powerful 1600W output ensures quick heating, and the adjustable temperature control up to 650°C allows you to work on different plastics without damaging them. This makes it suitable for both beginners and professionals, though beginners might need some practice to get the heat settings just right.

Most important from

113 reviews

Allturn Plastic Welder, 2 in 1 Plastic Welding Kit, Hot Staples Weld Gun, Car Bumper Repair Kit for Most Plastics, Patent Number D970324(Yellow)

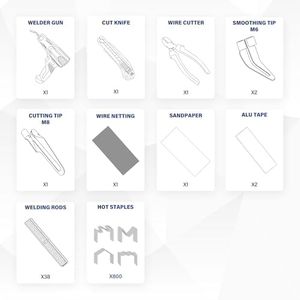

The Allturn Upgraded Plastic Welder is a versatile tool that shines in the realm of plastic repair, making it suitable for DIY enthusiasts and professionals alike. This plastic welding kit comes with an impressive range of accessories, including 800 plastic welding staples and various welding rods, which means you have everything you need to tackle a wide variety of plastic repairs, from car bumpers to household items. The ergonomic design ensures comfort during extended use, which is particularly beneficial for those tackling larger projects or multiple repairs in one session.

Most important from

5259 reviews

Top 10 Best Plastic Welders 2026 in the United States

Winner

WELDY 3400W Handheld Plastic Extrusion Welding Machine kit Hot Air Plastic Welder Gun Vinyl Weld Extruder Welder Machine (EX2)

WELDY 3400W Handheld Plastic Extrusion Welding Machine kit Hot Air Plastic Welder Gun Vinyl Weld Extruder Welder Machine (EX2)

Chosen by 1301 this week

SWIGRANCE Hot Air Plastic Welder 1600W, Complete Accessories & Nozzles for Plastic Welding Roofing Kit 110V, Vinyl PVC TPO Roof Handheld Hot Air Heat Gun Plastic Welding Torch

SWIGRANCE Hot Air Plastic Welder 1600W, Complete Accessories & Nozzles for Plastic Welding Roofing Kit 110V, Vinyl PVC TPO Roof Handheld Hot Air Heat Gun Plastic Welding Torch

Allturn Plastic Welder, 2 in 1 Plastic Welding Kit, Hot Staples Weld Gun, Car Bumper Repair Kit for Most Plastics, Patent Number D970324(Yellow)

Allturn Plastic Welder, 2 in 1 Plastic Welding Kit, Hot Staples Weld Gun, Car Bumper Repair Kit for Most Plastics, Patent Number D970324(Yellow)

JOUNJIP Plastic Welding Kit Deluxe -UL Certified Plastic Welder 80W Iron- Professional Grade Plastic Repair Kit for Automotive Car Bumper, Kayak, Tank Repair

JOUNJIP Plastic Welding Kit Deluxe -UL Certified Plastic Welder 80W Iron- Professional Grade Plastic Repair Kit for Automotive Car Bumper, Kayak, Tank Repair

Upgraded 220W Plastic Welder, 2 in 1 Plastic Welding Repair Welder Kit 1000PCS Hot Stapler Soldering Gun with 100PCS Plastics Welding Rods Car Bumper Repair Kit for Most Plastics(Black)

Upgraded 220W Plastic Welder, 2 in 1 Plastic Welding Repair Welder Kit 1000PCS Hot Stapler Soldering Gun with 100PCS Plastics Welding Rods Car Bumper Repair Kit for Most Plastics(Black)

220V EX2 EX3 WELDY 3400W Handheld Plastic Extrusion Welding Machine kit Hot Air Plastic Welder Gun Vinyl Weld Extruder Welder Machine (EX2 extruder)

220V EX2 EX3 WELDY 3400W Handheld Plastic Extrusion Welding Machine kit Hot Air Plastic Welder Gun Vinyl Weld Extruder Welder Machine (EX2 extruder)

Plastic Welder, 2 in 1 Plastic Welding Kit, SONNLER 1000PCS Hot Stapler Plastic Repair Kit For Car Bumper Crack Repair with Iron, Rods, Metal Mesh, Abrasive Paper, Aluminum Tape

Plastic Welder, 2 in 1 Plastic Welding Kit, SONNLER 1000PCS Hot Stapler Plastic Repair Kit For Car Bumper Crack Repair with Iron, Rods, Metal Mesh, Abrasive Paper, Aluminum Tape

Leister Triac ST 141.288 Hand Held Plastic Welder w/ 40mm Nozzle

Leister Triac ST 141.288 Hand Held Plastic Welder w/ 40mm Nozzle

ATOLS Plastic Welder, 1000PCS Staples, Plastic Welding Kit, Hot Stapler Kit, Plastic Welder Gun Kit, Car Bumper Repair Kit, Plastic Repair Kit

ATOLS Plastic Welder, 1000PCS Staples, Plastic Welding Kit, Hot Stapler Kit, Plastic Welder Gun Kit, Car Bumper Repair Kit, Plastic Repair Kit

Leister Triac ST 141.228 Plastic Welder With 20MM Nozzle, Seam Roller & Carrying Case

Leister Triac ST 141.228 Plastic Welder With 20MM Nozzle, Seam Roller & Carrying Case

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

![ARCCAPTAIN 200A Stick/Lift TIG Welder with Torch, [Large LED Display] 110V/220V Welding Machine with Synergic Control, IGBT Inverter, Portable MMA Welder Machine with Hot Start, Arc force](https://images-proxy.bestreviews.guide/Ytmi7FhelYm6C_LY3x2tpMBYAgg=/0x300/https://m.media-amazon.com/images/I/41WzQ-VHwuL._AC_CX679_.jpg)

![ARCCAPTAIN iControl ARC165 Pro Stick Welder, [APP Control] 165Amp ARC/Lift TIG Welding Machine, Large LED Display, IGBT Inverter 110V/220V MMA Welder with Hot Start, Arc force, and Anti-Stick](https://images-proxy.bestreviews.guide/ZYz_lm_B5mTItojTltW6E8fSq-Q=/0x300/https://m.media-amazon.com/images/I/51r7M3ZG0oL._AC_CX679_.jpg)